Fast, Precise and Automated Sample Preparation for Mineral and Ore Analysis

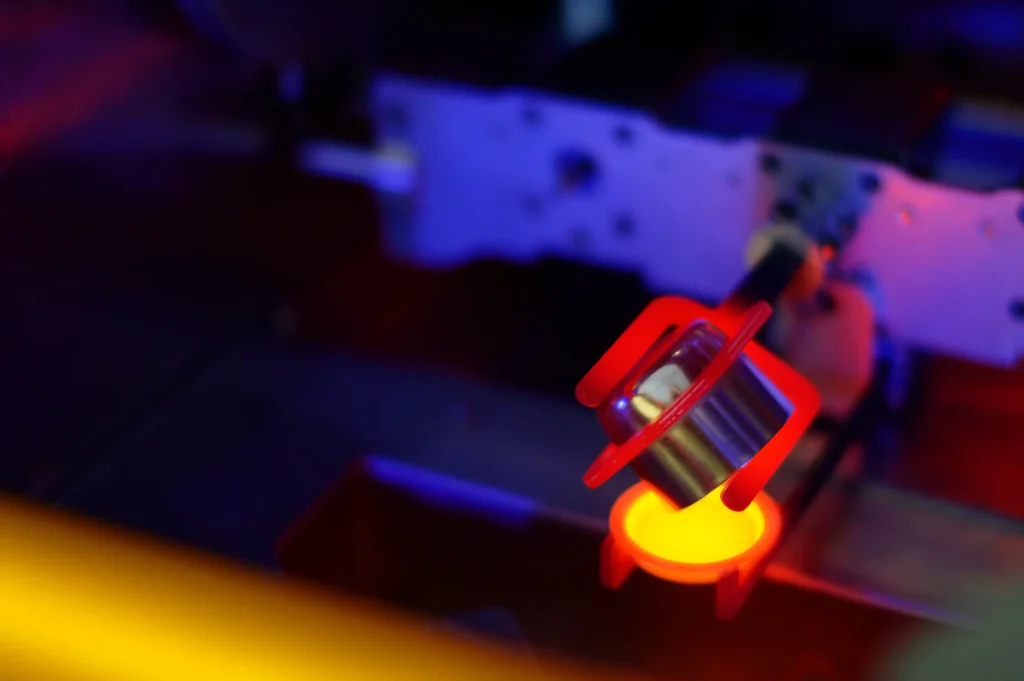

In mining laboratories, accurate elemental analysis is critical for mineral exploration, process control, and ore evaluation. Katanax fusion fluxers deliver consistent sample preparation through borate fusion, a proven technique that breaks down even the toughest matrices, ensuring reproducible results for XRF, ICP-OES and ICP-MS techniques.

Whether you are analyzing sulfate-rich ores, sulfides or rare earth metals, borate fusion takes difficult samples and transforms them into stable, homogeneous glass disks or solutions for high-precision elemental quantification.

Contact us today to learn how Katanax can optimize your mining laboratory sample preparation.

Why Use Borate Fusion for Mining Applications?

Borate fusion eliminates the need for harsh acids or inconsistent digestions. It is fast, repeatable, and designed for the complexities of modern mining laboratories:

- Excellent homogeneity ideal for XRF and ICP workflows.

- Complete dissolutions of refractory materials including silicates without HF.

- Accelerated sample processing enabling high-throughput to run efficiently

- Low contamination risk especially compared to acid digestion

- Reproducible results critical for geochemical and assay labs

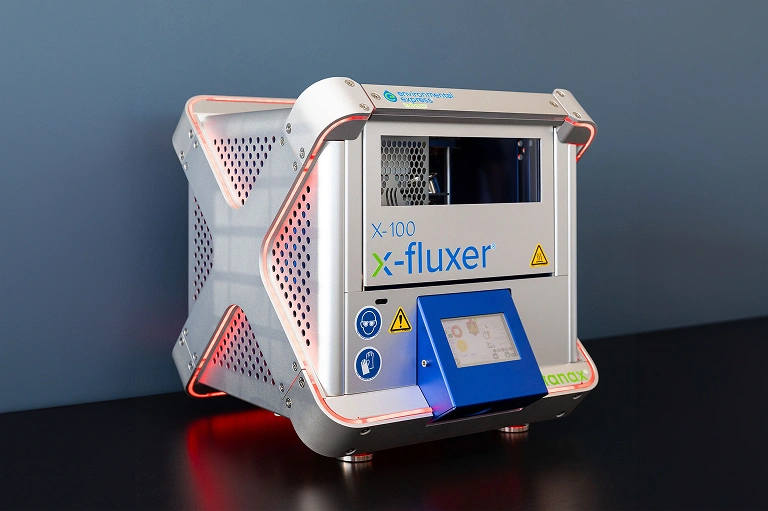

Katanax Fusion Fluxers: Engineered for Mining Laboratories

Katanax offers a range of electric fusion fluxers tailored to meet the demands of mining laboratories:

Advantages of Katanax Fusion Fluxers:

- Ease of Use: Plug-and-play design with pre-installed fusion programs and an intuitive icon-based interface.

- Safety: Fully enclosed safety shield and interlock system ensure operator protection.

- Environmental Considerations: Electric operation eliminates the need for combustible gases, reducing environmental impact, operational costs and safety.

- Automation: Fully automated processes allow unattended operation, increasing laboratory efficiency.

Optimize Your Mining Laboratory with Katanax

Katanax fusion fluxers are ideal for preparing a wide range of ore types, including:

- Iron and copper ores

- Base and precious metals

- Sulfides

- Process plant materials like slag and tailings

- Soil and rocks from exploration drilling

Katanax fusion fluxers support every stage of the mineral extraction and production workflow with rapid, repeatable results and automated operation.