Reliable Sample Preparation for Clinker and Cement Analysis

In cement manufacturing, elemental accuracy is essential for maintaining consistent product quality, optimizing process control, and meeting industry standards. Katanax fusion fluxers offer a dependable solution for cement laboratories delivering high accuracy, and reproducibility across a wide range of materials.

With advanced temperature control, flexible fusion programming, and optional modules for solution preparation, Katanax systems are built for the demands of high-throughput analytical workflows in cement laboratories.

Contact us today to learn how Katanax can optimize your cement laboratory sample preparation.

Why Choose Borate Fusion for Cement Analysis?

Borate fusion is ideal for preparing cement plant samples, from raw materials to finished products:

- Dissolve complex silicate-based matrices such as limestone, clay, shale, kiln dust, and clinker

- Eliminate matrix effects by producing uniform beads for high-quality XRF analysis

- Delivers accurate and repeatable results essential for process control and compliance

- Meets industry standards, including ASTM and ISO requirements

- Integrates seamlessly with existing workflows

Compared to press pellets or wet digestion, borate fusion ensures better accuracy, repeatability, and a safer preparation process.

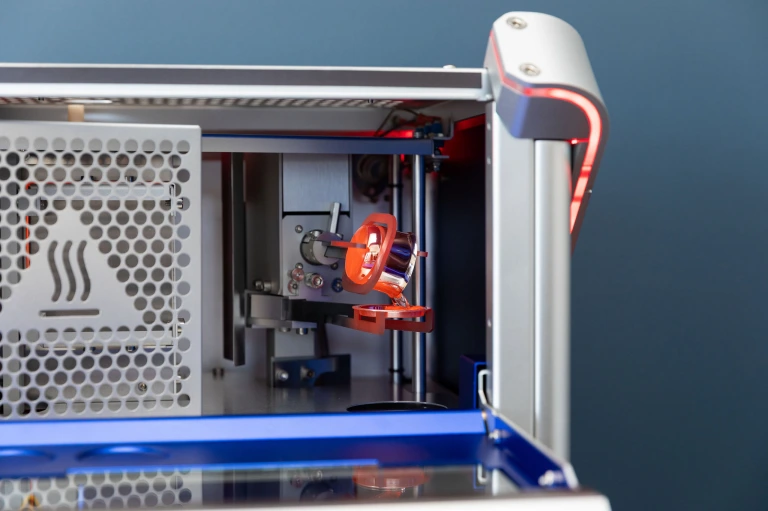

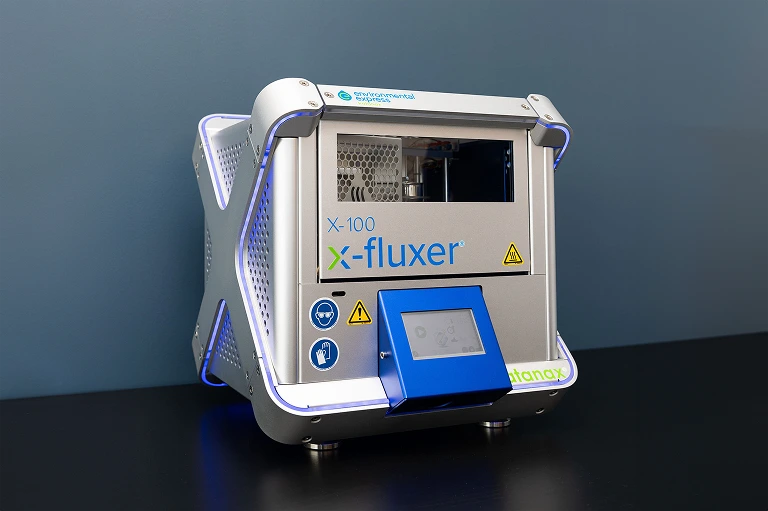

Katanax Fusion Instruments: Built for Cement Laboratories

Katanax fusion systems are engineered to meet the rigorous demands of the cement industry whether in central labs or production sites:

Key Benefits:

- Fully Electric Operation – No gas or flames ensuring a safer and cleaner lab environment

- Fast Cycle Times – Complete fusion in approximately 10–20 minutes

- High Reproducibility – Consistent results across multiple users and sample types

- Hands-Free Automation – Minimal handling reduces contamination risk and operator error

- Workflow Compatibility – Easily integrates with XRF, ICP-OES, and ICP-MS analytical methods

Trusted in Cement Analysis

Katanax fusion instruments are trusted by major cement manufacturers and analytical service laboratories worldwide for their ability to deliver consistent, high-precision results essential for routine production monitoring and long-term material certification.

Borate fusion has become a critical method in cement sample preparation, offering superior control over clinker composition, raw mix optimization, and compliance with final product specifications.

Engineered for efficiency, safety and reproducibility, Katanax systems enable accelerated throughput, stable operating conditions, and reliable analytical outcomes across diverse sample types.